What we do

At Paul Engineering, we are dedicated to delivering exceptional precision machining solutions for a diverse range of industries, including automotive, heavy plant, marine, and medical equipment. With a commitment to innovation and quality, we leverage cutting-edge CNC technology, drilling, milling, and heat treatment processes to manufacture specialist parts tailored to our clients’ unique needs. Our experienced team of engineers and technicians work collaboratively with clients to ensure every project is executed to the highest standards, enhancing performance and reliability. As a trusted partner in manufacturing, we strive to exceed expectations, driving advancements and supporting the success of our customers in an ever-evolving marketplace

Our Key Capabilities

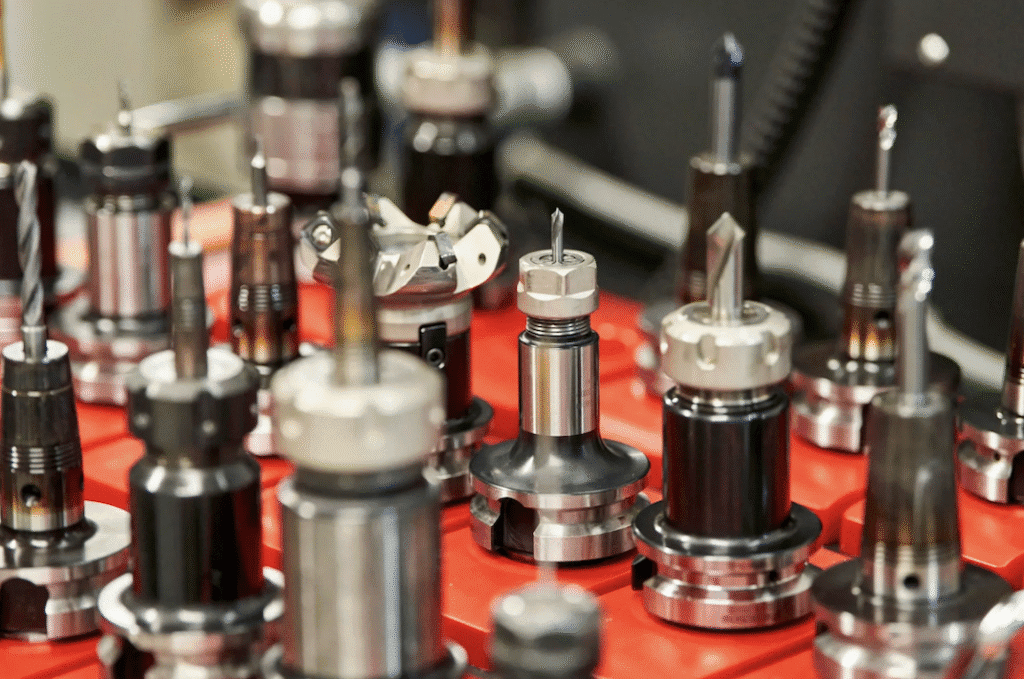

1: CNC Machining

Utilising advanced CNC technology, we provide precision machining services that produce high-quality components with tight tolerances. Our capabilities include 3-axis and 5-axis machining, allowing for the creation of complex geometries and intricate designs.

2: Drilling & Grinding

We offer a comprehensive range of drilling and grinding services, ensuring precise hole placements and smooth surface finishes. Our state-of-the-art equipment enables us to handle various materials while maintaining strict quality standards.

3: Milling Services

Our milling capabilities allow us to create a diverse range of parts with flexibility and efficiency. From custom projects to high-volume production runs, we can accommodate various sizes and shapes, catering to the specific needs of our clients.

4: Induction Heat Treatment

We specialise in induction heat treatment processes that enhance the mechanical properties of metal components, increasing hardness and wear resistance. This capability ensures that parts can withstand demanding applications, extending their longevity and performance.

5: Material Expertise

Our team has extensive knowledge of working with a wide variety of materials, including metals, plastics, and composites. This versatility allows us to select the most appropriate material for each application, ensuring optimal results for our clients.

6: Quality Assurance

We implement rigorous quality control measures throughout our production processes, utilising advanced inspection techniques to guarantee that every part meets the highest industry standards. Our commitment to quality ensures that our clients can rely on our components for their critical applications.

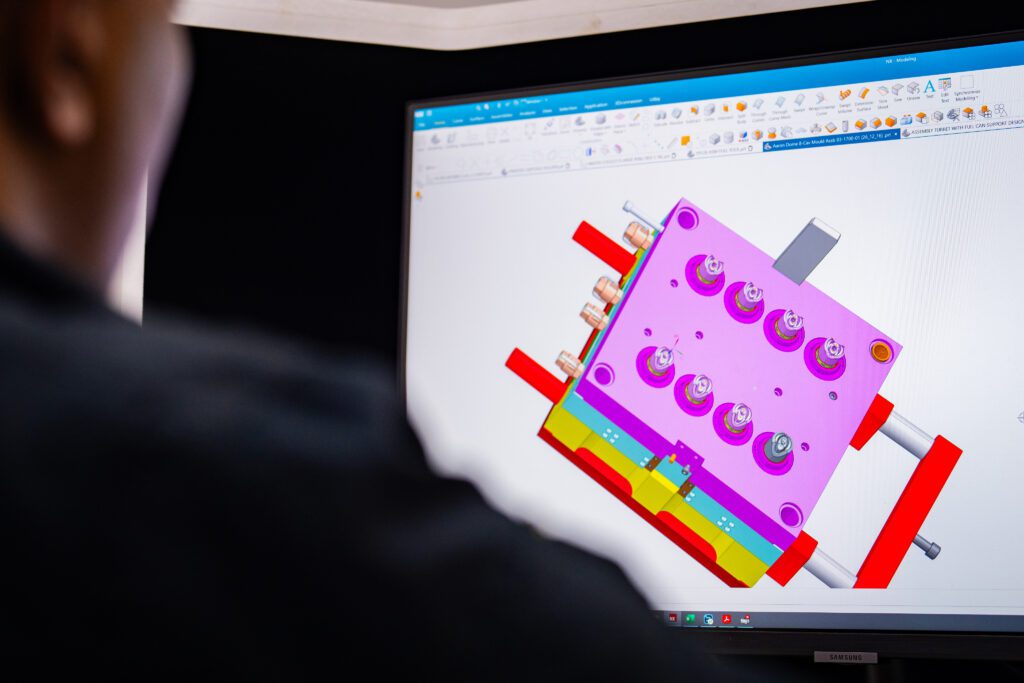

7: Custom Solutions

Understanding that every client has unique specifications, we pride ourselves on offering custom machining solutions tailored to individual needs. Our collaborative approach involves working closely with clients to develop and deliver parts that align with their specific requirements.

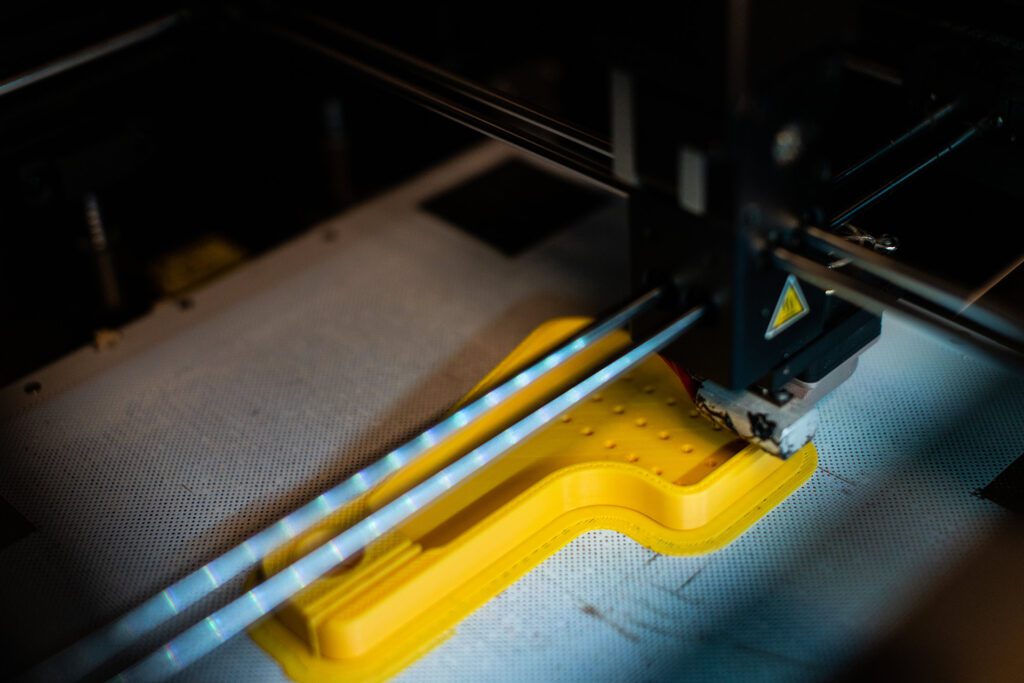

8: Rapid Prototyping

We provide rapid prototyping services, allowing clients to quickly test and validate designs before full-scale production. This capability accelerates the product development cycle and fosters innovation.

9: Industry Expertise

With experience across various sectors, including automotive, heavy machinery, marine, and medical equipment, our team understands the unique challenges and requirements of each industry, ensuring we deliver relevant and effective solutions.

10: Sustainability Initiatives

We are committed to sustainable manufacturing practices, implementing eco-friendly processes and reducing waste as part of our operational goals. This focus on sustainability not only benefits the environment but also enhances our clients’ brand values.